Enabling Growth in the

New Anglia Advanced

Manufacturing &

Engineering Sector

through Skills

Development

2018-‘25

New Anglia LEP Sector Skills Plan - Advanced

Manufacturing & Engineering

January 2018

1 | P a g e

Contents

Background Context

2

Executive Summary

3

Overview of the Advanced Manufacturing and Engineering Sector

4

Sector Definition

6

Skills & Workforce Supply

7

Opportunities and Challenges

10

The AME Sector Skills Plan

19

Priorities for Action

19

Need for a Step Change

20

AME Sector Skills Plan Delivery

21

Proposed Skills Interventions

23

Appendix A - Sector Skills Plan Development Process

28

Consultees

29

Appendix B - Summary of DataPack & Other Sector Intelligence

31

Links to Other Sector Skills Plans

35

Appendix C - Current Skills and Training Provision for AME

37

Task and Finish Groups

44

Annex 1 - East of England Science and Innovation Audit (SIA) Extract adapted from the

Summary Document:

50

2 | P a g e

Background Context

The Advanced Manufacturing and Engineering (AME) Sector Skills Plan has been

developed by the AME sector in Norfolk and Suffolk, working alongside the New Anglia

Local Enterprise Partnership, the New Anglia Skills Board and supported by SkillsReach.

SkillsReach was contracted to facilitate and prepare eight sector skills plans for the New

Anglia LEP priority sectors. The project was commissioned by the Education and Skills

Funding Agency, in partnership with New Anglia LEP, and funded through the European

Social Fund. Each Sector Skills plan and supporting Data Pack has been developed in

collaboration with local employers and other stakeholders.

The Advanced Manufacturing and Engineering Sector Skills Plan has been developed in

partnership with the New Anglia Advanced Manufacturing and Engineering (NAAME) sector

group, the lead organisation taking forward the further development and implementation of

this plan in conjunction with New Anglia LEP, local education institutions and other

stakeholders and key sector champions.

The New Anglia Skills Board places employers at the centre of decision making on skills in

Norfolk and Suffolk to ensure the skills system becomes more responsive to the needs of

employers, and the future economy.

NAAME’s Sector Growth Strategy1 (2017) focused on six areas to drive sector growth:

Financially backing the sectors as drivers of economic growth;

Embed supply chains and knowledge locally;

Bring together businesses in special interest groups;

Improve the infrastructure across Norfolk and Suffolk;

Increase the engagement between schools and businesses;

Focus on New Anglia’s emerging sub-sectors.

SkillsReach is an established East of England-based strategic skills consultancy with an

associate project team with extensive experience of developing skills plans.

1 Hethel Innovation, NAAME Sector Group (2017), Norfolk and Suffolk Sector Growth Strategy: Advanced

Manufacturing and Engineering

3 | P a g e

Executive Summary

Advanced Manufacturing and Engineering (AME) is a large and dynamic sector in the New

Anglia economy and one that the area wishes to prioritise given the high skilled, high wage

profile of the sector.

The sector is, however, facing significant challenges in meeting its future workforce and

skills needs and expected changes in the industry are likely to exacerbate this challenge.

Notably the engineering and manufacturing sectors are on the cusp of widespread adoption

of new technology, often called Industry 4.0 or the 4th Industrial Revolution, through which

traditional engineering is becoming intimately entwined with sensors, automation and ICT.

These changes in the context for the industry are an enormous opportunity and one which

we know will change the skills we need, probably ultimately in ways we have not yet even

considered. As with earlier industrial revolutions the prize is economic growth, better and

safer working conditions and enhanced life opportunities, but Norfolk and Suffolk are not

alone in the race to adopt this new technology.

The skills that our existing workforce have and continue to develop will help us lead this

process of change, but we also need to attract many more young people by helping to

describe clearly how a career in our industry is dynamic and has real prospects. If we are

right about Industry 4.0 these prospects will not only be in the traditional AME sector, the

skills we have in manufacturing and engineering will also be enablers of change right across

the economy, from health care to transport to food production and science.

We propose to work on four supplementary areas to support the focus on Industry 4.0:

Careers of the Future to ensure the sector projects its career opportunities effectively;

Developing AME Course Provision to ensure courses meet changing employer needs;

Physical Facility Development to ensure we increase the capacity for training;

Tutor Development to increase the supply of tutors to train more people in AME skills.

Every sector will need our support to embrace the opportunities automation and ICT can

bring and will need to draw on skills in advanced manufacturing and engineering. The task

before us is therefore a once in a generation opportunity to rethink our skills system, with

employers working with education and skills providers to rise to the opportunity.

The New Anglia Advanced Manufacturing and Engineering (NAAME) sector group is

pleased to be helping to drive this agenda and look forward to working with you so that

together we can meet the future skills needs of the industry.

NAAME sector group, January 2018

Acknowledgements

The New Anglia LEP wish to thank the employers, providers and stakeholders who

contributed to the plan by attending events, being interviewed or by making referrals to

employers and organisations in the sector. The sector skills plan was developed in 2017/18

by SkillsReach.

4 | P a g e

Overview of the Advanced Manufacturing and Engineering Sector

In total the Advanced Manufacturing and Engineering (AME) sector currently employs

84,500 people in the New Anglia area, approximately 11% of the workforce. Employment in

the sector has fallen by three per cent since 2010 (-3,100 jobs).

The inclusion of food manufacturing within the defined sector means that the sub sectors of

‘Processing and preserving of poultry meat’ and ‘Production of meat and poultry meat

products’ are the first and third largest with 4,600 and 3,200 workers respectively2. In second

place is the sub sector ‘Other engineering activities’ with 4,500 workers.

In terms of Gross Value Added (GVA) the sector in 2015 was worth approximately £5.1bn to

the LEP area, which equates to just over 14% of the total New Anglia economy. This is an

increase of £745m on 2010 (+17%) but does mask a drop in GVA between 2014 and 2015

of just over £60m.

The higher share of GVA (14%) compared to workforce (11%) shows that the sector has a

higher per capita GVA than the economy as a whole, which given full or very close to full

employment in the LEP areas suggests that a focus on growing this sector would allow the

economy to expand even without additional net employees in the LEP area. The GVA per

capita employed is £60,355.

In 2016 there were 6,040 AME enterprises operating in the New Anglia area, or 10% of all

enterprises. Since 2010 the number of Advanced Manufacturing and Engineering

enterprises has increased by 425, or around 8%, which is below the total New Anglia rate of

growth for enterprises of just over 9%.

Given the smaller share of enterprises (10%) than share of the workforce (11%) or

contribution to GVA (14%), the data suggests that enterprises in the sector are both larger

and more productive than the average for all enterprises in the LEP area.

The growth in New Anglia AME sector GVA since 2010 is higher than national and regional

averages of +15%, higher than Greater Lincolnshire LEP (+1%) and South East LEP (-2%),

but below Greater Cambridge & Greater Peterborough LEP (+27%).

Nationally, employment in the sector grew 3%, whilst South East LEP has seen a decrease

of -6% since 2010. Greater Cambridge and Greater Peterborough LEP AME employment

increased in line with nationally trends and Greater Lincolnshire had an increase of +10%.

The Suffolk Limited report (2017)3 includes 10 manufacturing businesses in its top 100

Suffolk companies employing 2,000 staff (excluding the largest employers such as Greene

King). These companies showed a year on year growth of +24% for turnover and +53% for

operating profit, showing that this mid-tier of medium and larger companies are seeing

strong growth, with this sector growing faster than the average for all companies in Suffolk.

2 The food processing sector was covered in more depth in the New Anglia AgriFood Tech Sector Skills Plan

developed by the LEP in 2017

3 Grant Thornton, Birketts (2017), Suffolk Limited 2017: Growth in Interesting Times

5 | P a g e

The AME industry is diverse and includes technology providers, underpinning R&D centres

and innovative companies, but in addition many specialist engineers and manufacturing

trained staff are employed directly in businesses which make, service or install a wide range

of other products or services. The manufacturing sector is increasingly high tech and across

many industries advanced manufacturing principles are now being applied, including in:

Automotive, trailers and vehicles

Boatbuilding

Aerospace

Bio-economy

Robotics, automation, ICT equipment

Health equipment

Chemicals

Construction

Energy, oil and gas

Offshore and marine

Agrifood automation (Norfolk and Suffolk

SME base strong)

Engineering is both a sector in its own right and a source of skills for many other companies

in virtually every sector given the pervasive use of engineering in virtually every workplace.

Defining the Scope

The adopted scope is:

Engineering companies

Manufacturing companies

Technology suppliers

R&D centres and providers

Engineering and manufacturing consultants Training providers

Many larger manufacturers and service sector companies also have in house engineering

capability e.g. most food companies have an in house engineering team as well as

employing external contractors, the same is true in logistics and other similar sectors.

Over 30% of the top 100 companies (by sales) in Norfolk and Suffolk4 are in the

manufacturing and engineering sector, with over 60% of the total turnover being in food

manufacturing. This focus on larger employers also means the sector is likely to be a major

contributor to the Apprenticeship Levy with work by SkillsReach (2017) suggesting that 21%

of the levy in New Anglia, circa £10.5m, will be paid by advanced manufacturing with a

further 24% in the agrifood tech sector (£12m), much of which relates to larger food

manufacturing companies.

As well as larger employers the AME sector includes a large number of SMEs as

manufacturers or as service providers.

Future Growth potential

Major developments in the industry in New Anglia will drive local growth, including notably:

The continued growth of Hethel Innovation (including Lotus cars - recently acquired by

Geely the Chinese owner of Volvo and associated companies);

4 EDP and EADT (2017), top 100 companies

6 | P a g e

The development of the A11 technology corridor to Cambridge focused on the AME

sector is a core part of the economic development agenda for the Councils on the route;

The Norwich Aviation Academy;

Investment by the MOD in new engineering capacity, for example the confirmation of

RAF Marham as a long term strategic base for strike aircraft including its Engineering &

Logistics Wing (ELW);

The potential development of Sizewell C in Suffolk could lead to further substantial

growth of the sector in the New Anglia area in the medium to long term.

The energy, logistics and construction sectors are also witnessing steady growth, much of

which is increasingly using AME technologies and expertise.

The perception of consultees was that the sector is currently seeing slow but steady growth

with new regulations, market needs or technology driving a need to upgrade existing

equipment e.g. new refrigeration regulations in 2020.

In other parts of the industry the use of new machines, such as CNC lathes, which typically

cost £200-400,000 and require high levels of ICT skills as well as engineering skills, will

continue to change the sector and lead to higher productivity and growth. However,

consultees were concerned that the UK is ‘behind the curve’ and has been slow to adopt

these types of new systems and equipment compared to other countries.

Sector Definition

The sector definition applied to the recent New Anglia LEP Economic Strategy Evidence

Base, and reproduced here, encompasses all manufacturing activity in the area, as opposed

to highlighting only the ‘advanced’ elements and engineering. The rationale, endorsed by

consultees is that all manufacturing now has to be ‘advanced’ if it is to be competitive5.

This wide definition means that there are sizeable overlaps between the AME sector and

AgriFood Tech (food and drink manufacturing), Digital Tech (printing and publishing), Life

Sciences & The Bio-Economy (Manufacture of pharmaceuticals; precision instruments),

Transport & Logistics (Repair and maintenance of lorries, ships, aircraft etc.), and Tourism &

Culture (Manufacture of Jewellery, musical instruments, games etc.).

To help identify the breadth of the sector, its major sub-sectors and constituent companies,

Hethel Innovation (2017) has developed sector reports for High Value Manufacturing and

Engineering6 which show how vibrant and diverse the AME sector is in New Anglia. These

reports will support sector growth and networking programmes run by NAAME.

5 The only exception would be the limited niche market for handmade, traditional products which make a

virtue and marketing proposition from not using modern automated or highly technical production methods.

Whilst there is a growing market for these speciality products, consultees felt that they would remain a niche

market with a low overall percentage market share

6 Hethel Innovation (2017), Network Development Reports for High Value Manufacturing and Advanced

Engineering: precision engineering; automotive sector; advanced materials - composites; electronics sector

7 | P a g e

Skills & Workforce Supply

Analysis of LEP level results for the ‘Manufacturing’ sector from the UKCES Employer Skills

Survey 2015 shows that the ‘Manufacturing’ sector was more likely to report skills shortage

vacancies (28%) as a proportion of all vacancies than both the New Anglia all sector (19%)

and national (23%) averages. Evidence suggests that, as consultees reported, productivity

is improving but there is uncertainty about future workforce size.

In total, 6,820 learning aims related to the AME sector were delivered to New Anglia

residents in 2012/13, 8.5% of all learning aims delivered in New Anglia, compared to 5.8%

for the AME sector nationally. Since 2010/11, there has been an 18% increase in the

number of AME learning aims delivered to New Anglia residents. This contrasts with a

national decrease of 3%, which suggests that the sector locally is bucking the national trend

and trying to ensure that future workforce skills needs are met.

Analysis of data sourced from the Department for Education’s Further Education data library

based on the Sector Lead Bodies identified as being the most relevant to the AME sector:

Process Manufacturing; and Science, Engineering & Manufacturing, shows that the majority

of these learning aims (5,360 or 79%) achieved by New Anglia residents were delivered by

New Anglia based providers. This is slightly more than the average for New Anglia across all

sectors (75%) suggesting the sector is relatively well supported by local skills providers.

Provision of Advanced Manufacturing & Engineering learning aims by New Anglia providers

to New Anglia residents has increased, with growth strongest in ‘Process & Manufacturing’

at +54%, though the majority of learning aims are still delivered under ‘Science, Engineering

& Manufacturing Technologies’ with 3,110 registrations.

In 2015/16 there were 1,810 starts in ‘Engineering and Manufacturing Technologies’

apprenticeships in New Anglia, 13% of all apprenticeship starts in the area. Growth over time

in ‘Engineering and Manufacturing Technologies’ apprenticeship starts is below that of

regional and national comparators, and that of growth in the number of apprenticeship starts

overall. Data on apprenticeship participation by sector provides a slightly different

perspective with the Manufacturing sector accounting for 8.4% (2,580) of all apprenticeships

in 2014/15, which is lower than the level of employment in the sector at 11%.

Despite recent growth in participation rates locally, 22% of manufacturing employers in New

Anglia reported having staff that were not fully proficient in 2015, compared to an average of

14% nationally, suggesting that further growth in investment in staff training is needed. This

is confirmed by the fact that staff not fully proficient as a percentage of employment in the

sector was 5%, above the New Anglia average of 3% but in line with regional and national

rates. The data points to staff not being fully proficient as an issue particularly for smaller

employers.

UKCES data and the East of England Forecasting Model suggest that the sector is projected

to decline in employment between 2014 and 2024 by circa 10% (approximately 8,000 jobs).

However, this projected decline is not reflected by local employers who, subject to continued

favourable business conditions and workforce supply, expected slow but steady growth.

8 | P a g e

Even if the sector does see an overall decline in employment, there will still be growth areas

within the sector with around 7,000 new jobs forecast over this period. In addition,

replacement demand is expected to be somewhere in the region of 30,000 jobs.

This suggests a net requirement for new staff in the sector at 37,000 over the decade from

2014-2024. New jobs creation (expansion demand) will be primarily in roles requiring

degree level skills and higher (Level 4 and above) with job losses in lower skilled roles.

Despite the overall projected decline in job numbers there will still be growth areas within the

sector with around 7,000 new jobs at Level 4 to 6 (HE to First degree level) and above

(figure 1) and a projected small increase in the number of post graduate level roles, with in

total over 7,500 additional jobs created in the AME sector for those with L4+ qualifications.

In contrast at L3 and below the number of employees is projected to fall, with an overall fall

of over 15,000 job roles at this level. This is consistent with feedback from consultees, who

universally predicted a continued need to upskill the workforce as new technology drives the

sector forward.

At the same time, there will be a significant number of existing jobs to replace as people

leave the sector workforce. The replacement demand at both ends of the skills range, for

those staff with no qualifications/level 1 and at the other end levels 7-8 are very modest.

Most replacement demand is focused on levels 2-6, with the demand for L2, L3 and L4-6 all

fairly even.

Fig 1 Projected future skills demand by level for New Anglia AME sector

-5,000

-2,500

0

2,500

5,000

7,500

10,000

12,500

15,000

QCF 7-8

QCF 4-6

QCF 3

QCF 2

QCF 1

No Qual

Expansion Demand

Replacement Demand

9 | P a g e

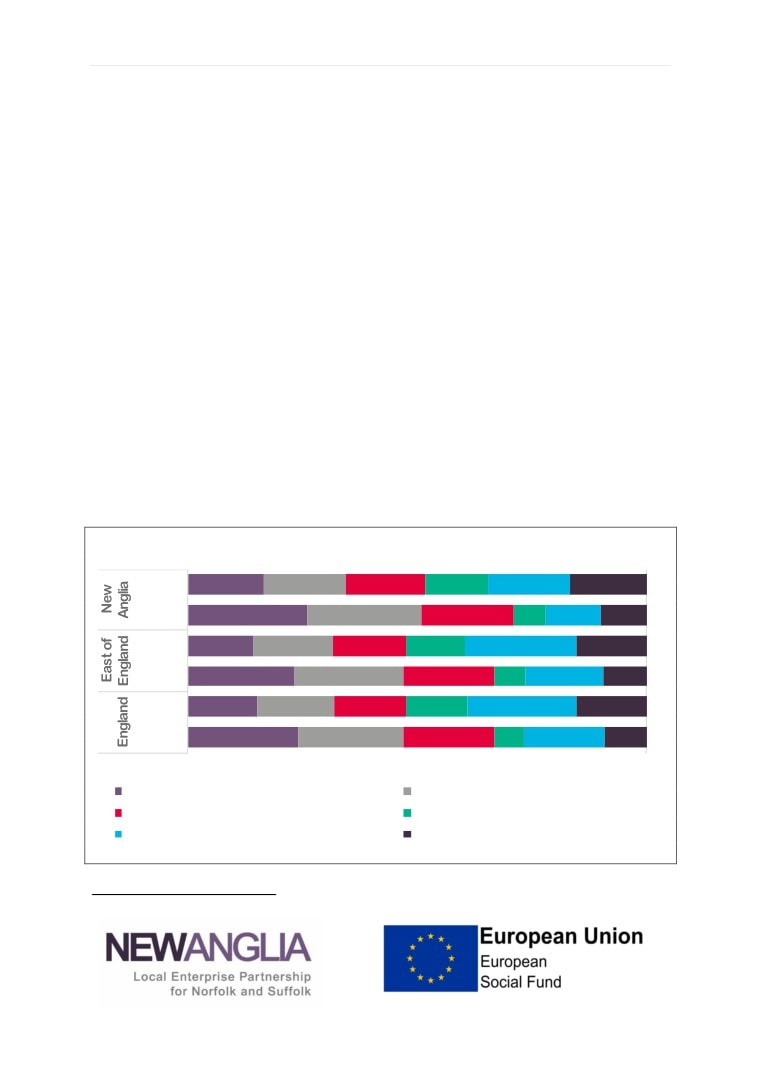

Advanced Manufacturing & Engineering Skills Supply and Demand

As with the overall workforce in New Anglia, the AME workforce is becoming more highly

skilled as analysis of 2001 and 2011 Census data shows (figure 2). However, in terms of the

shift in qualification levels, New Anglia still lags behind regional and national averages for

the AME sector. Nonetheless, the demand for L3 or L4+ skills increased from 19% to 32%

over the decade to 2011 and consultees reported that they believed it has continued to grow

since 2011 and will do so in future. This trend can be seen in changes in qualifications in the

sector between 2001 and 2011 (figure 2).

The trend in the qualifications profile in New Anglia (figure 2) shows that the industry has

been managing this change to higher qualifications for many years which should help to

meet the anticipated future demands (figure 1).

UKCES (2015)7 found that New Anglia manufacturers on average are marginally less likely

to have vacancies than local, regional and national averages. However, companies with

vacancies are much more likely to report these as being Skills Shortage Vacancies (SSVs).

The AME sector’s performance against training measures (such as the provision of training

in the last year, and on-the-job training) shows that it is either broadly in line or above local,

regional and national averages for all indicators compared to other sectors, apart from online

or e-learning training. Similarly, training days per trainee and trainee days per staff, are both

much higher than all comparators.

Manufacturing employers are also less likely to report underutilised staff than local, regional,

and national averages for all sectors, 21% compared to 25%, 25%, and 30% respectively.

Fig 2. Qualification profile in the AME sector

2011

16%

18%

17%

14%

18%

17%

2001

26%

25%

20%

7%

12%

10%

2011

14%

17%

16%

13%

24%

15%

2001

23%

24%

20%

7%

17%

9%

2011

15%

17%

16%

13%

24%

15%

2001

24%

23%

20%

7%

18%

9%

0%

100%

No qualifications

Level 1 qualifications

Level 2 qualifications

Level 3 qualifications

Level 4 qualifications and above

Apprenticeships and other qualifications

7 UKCES (2015), Employer Skills Survey 2015

10 | P a g e

Opportunities and Challenges

Employers and consultees identified a wide range of key workforce and skills challenges

which need to be addressed to facilitate future growth of the AME sector, including:

Workforce supply:

Recruitment of experienced staff (30+age group) is generally done through national

advertising using recruitment agents as there is a lack of local supply and this is not

expected to change as employers want to attract the best talent available nationally.

One specific challenge noted by employers was the hourglass age profile of the

workforce, with a noticeable gap in many companies workforce in mid career staff what

one consultee called a ‘missing generation’, and a problem despite a recent increase in

recruitment at younger ages that as the older workforce retires the next generation (30-

45 age group) who would be expected to replace them is missing.

Specialist CPD for the existing workforce is also a national market as there is not enough

local demand to offer courses in all areas given the multitude of different specialist skills

needed across the AME sector. The demand for CPD is expected to grow given the

speed of change in the industry and the technology the AME sector is using. Consultees

also reported a frustration that in their view there were no programmes in place for older

experienced people to retrain / gain skills to help fill the gaps in industry workforce

supply.

Some work e.g. engineering design work, is being contracted out of the region or UK to

access specialist skills available globally. This is the reality of modern global supply

chains and it is important for New Anglia to be clear on which parts of the industry to

focus local skills initiatives on as the area cannot lead on all areas and, as a

consequence, to accept that for some other skills it may be preferable to work with global

centres of expertise.

Many staff, estimated across the engineering sector at 10-11%, come from other EU

states and this is creating additional uncertainty for the future given the likely restrictions

employers expect after Brexit. Many agencies which help to fill short term gaps in

workforce supply have a much higher % of their workers drawn from overseas and in

2017 have started to struggle to meet company needs.

Current course provision:

Some sub-sectors within AME don’t have appropriate apprenticeship provision e.g.

ventilation engineering.

There is also a more general concern that the apprenticeship frameworks are very rigid,

overly prescriptive and don’t meet the needs of many companies in the sector.

Feedback shows that in this sector both providers and employers are frustrated by the

inability to flex course content to meet employer needs, with employers saying that this

means they are not able to use government endorsed training to meet their needs. They

believe that as the system changes to one in which employers are expected to pay more

of the cost of the training provided that this must change so that the customer receives

what they want to pay for.

Current FE course funding mechanisms are overly prescriptive and are stopping new full

time provision which responds to challenges such as Industry 4.0, because the current

funded frameworks don’t allow students to combine aspects of engineering, ICT and

11 | P a g e

electronics which are needed to meet this. This requires new standards and frameworks

which are aligned with emerging industry needs or the freedom locally to adapt a light

touch national framework to meet local employers’ needs.

Similar development needs to happen in specialist AME areas such as the Aviation

sector to ensure that courses at IAAN are fully compatible with both funding models and

industry needs. In most cases this challenge requires more flexible funding.

There is also a perception that education exit points don’t meet industry needs and

expectations, whether at school or University/College level. Key challenges exist in

relation to technical and employability skills of those entering the industry. Employers

reported that even graduates or post graduates need to be viewed as ‘trainees’ for 3-4

years when they arrive in a company, as in most cases they lack the practical and

commercial skills needed and are not ‘job ready’.

There is also a need for clearer pathways for engineering / manufacturing career

progression through vocational progression and from FE to HE, as well as academic

routes. Several employers and national representative bodies, however, view the

current apprenticeships as much weaker than traditional courses as they are shorter,

less comprehensive and thus don’t in their view equip students with the skills needed.

Employers who visit schools to ‘sell’ the apprenticeship offer also reported concerns that

they find most pupils and staff don’t see apprenticeships as the preferred route post

school and this makes it hard to attract the best young people.

Some businesses reported that they have moved provider (within the region mainly) due

to problems with the quality of provision and because they were sent students who did

not meet industry needs.

There is a need for both core generic skills and in company expertise (given the diversity

and very specialist nature of most companies in the AME sector), with employers

recognising that they have a key role to play in the more specific company focused skills,

but in many cases frustrated at the lack of generic skills amongst students and new

recruits. The generic skills which employers require include: control systems, digital,

programming, servos/motors, fluid dynamics, new materials, additive manufacturing,

energy efficiency, communications and STEM foundations. Engineers also need to

develop basic hand skills to use tools and to have dexterity.

Some employers also reported that they were so confused or concerned by the way the

apprenticeship was working that they had decided to ignore the (new) apprenticeship

system and to recruit their own apprentices, outside the system, and deliver their own

training without trying to secure funding through the levy.

Overall though employers still felt that the current focus on apprenticeships, whilst

welcome, had come too late and that it was now imperative for everyone in industry and

government to come together to recruit and train more apprentices. There was also

widespread support amongst consultees for the development of degree apprenticeships,

but a recognition that awareness amongst young people and their families was still too

low and many still viewed apprenticeships as of less value than the academic route of ‘A’

levels followed by a degree.

Concerns were also expressed by both individual employers and sector bodies that the

new apprenticeship funding model was not working very well. The main concerns are

that the restrictions within the system make it very hard to access the levy funds because

in many cases the standards are not ready, providers are not ready or employers are

having problems accessing the online system. As a result it was felt that many

12 | P a g e

employers had decided to shelve plans for apprentices until system challenges have

been resolved.

Employers are also concerned that the current set of apprenticeship frameworks still

have significant gaps and this leaves many employers unable to access appropriate

provision to meet their needs.

Industry and stakeholder views on the responsiveness of skills provision:

The ‘stop/start’ nature and complexity of skills funding and initiatives is a major problem

in retaining AME employer commitment and interest in skills programmes. More stability

and longer term commitment of government funding in the system would give employers

the confidence to invest alongside the public sector. Other employers pleaded for

government to ‘stop changing / messing around with what’s going on in schools, i.e. the

exam results are no longer A, B, C etc and are now 1, 2, 3 etc… nobody has informed

employers what the grade systems equate to so how on earth do we know.’

The ageing workforce and major new developments, such as the potential Sizewell C

plant, means that there are growing concerns about the security of future workforce

supply locally as new demands for staff and skills compete with existing employers.

The skills supply for some substantive sectors, e.g. polymers, is currently lacking and is

not addressing market needs (although there is some limited national provision, this is

not sufficient to support the sector’s growth potential).

Networking is poor both between education providers and business and between

businesses themselves in the AME sector. The business community needs to do more

to support each other and promote the sector as a career of choice.

The importance of 'REAL' Work Experience to inspire young people and its perceived

current dysfunctional nature from an employer perspective, means the sector is finding it

hard to attract the next generation it needs to support its growth aspirations.

There is lots of potential locally to address these concerns, with some innovative ideas

progressing such as Institute of Technology (IoT) and the Institute of Productivity, but

these need to ensure they are delivered in ways which are responsive to industry needs.

Interestingly though one consultee noted that there was also a problem with some

employers not releasing staff for training even when this was provided free by component

suppliers: ‘I am observing widely that (electronics) vendors can’t give away valuable

technical training in the UK. In Europe they can fill a classroom, in the Far East a lecture hall,

in the UK if they don’t cancel the event it is virtually a one to one session’.

College and University facilities and staffing:

There are recognised major challenges in relation to the level of skills and industry

awareness amongst teachers and lecturers given the speed of change in the industry

and the recognised challenges of recruiting teaching staff in AME disciplines.

More broadly there is a problem in recruiting the lecturers and teachers needed in

technical and engineering disciplines. The feedback from providers is that this problem

is becoming acute in some areas due to rising salaries in the commercial sector that

educational providers cannot compete with. There is also a recognition that this problem

may well be exacerbated by the need to deliver more higher level provision and to

embrace new topics, such as Industry 4.0, which require multi-skilled tutors who can

combine expertise in engineering with ICT.

13 | P a g e

Some employers find it hard to engage with Colleges as course planning is poor or late,

making it hard for employees and learners to fit the course around work. Others noted

that they now, for example for mechanical apprentices, use national EEF provision in

Birmingham due to a perception that local provision is of poorer quality. Other

employers noted that they were working with national providers e.g. Loughborough

University to develop chemical engineers due to lack of suitable local provision.

Employers recognised that Colleges faced problems accessing modern equipment for

training and a significant number said that they would be willing to work with providers to

address this challenge by sharing facilities. In a few cases this was seen as working well

e.g. International Aviation Academy Norwich, but there was a general feeling that this

could usefully be extended to other areas.

Specific areas with skills gaps identified by local employers included:

Electrical, instrumentation and control engineers where technicians are hard to find and

experienced engineers (graduate level) are very scarce leading to many companies

poaching from each other;

Mechanical engineers and mechanical engineering companies are both in short supply

so it is hard to obtain the skills needed even if you try to sub-contract the work;

Composites engineers are in short supply in a sub-sector with good growth potential and

a strong local sector in New Anglia;

Embedded software which enables small devices to support the Internet of Things (IoT)

by coding and communications via USB, Ethernet and radio - this requires a

combination of engineering and computing skills;

Chemical engineers and organic chemists, because whilst there are ‘lots of graduate

chemists available [there are] few with knowledge of organic chemistry synthesis’;

Ventilation systems, not least due to forthcoming regulatory changes which will increase

demand in this sector;

The rapid growth in additive manufacturing and 3D printing which will impact across all of

manufacturing and potentially in major new markets such as building.

Regional connectivity with neighbouring areas and national provision:

Consultees were keen to stress that the AME sector is not constrained by LEP

boundaries and many businesses and supplier/client relationships cross over LEP

boundaries.

Similarly staff and education provision crosses these boundaries, with notable AME

training providers in the West of the region, e.g. College of West Anglia and West Suffolk

College, having strong links into Cambridgeshire through their provision and student and

employer base. These linkages also include the need to link with national provision such

as the Institute for Manufacturing (IfM) and Welding Institute both of which are just

outside New Anglia.

In developing the New Anglia plan it is therefore important to ensure that opportunities to

collaborate with other areas are taken.

14 | P a g e

National and Regional Reports

The feedback from New Anglia employers and stakeholders is broadly consistent with

national and regional reports on the challenges and opportunities in the AME sector.

Notable recent national and international reports which deal with this sector include:

The Industrial Strategy (2017)8 sets out how the government see the UK economy

changing and how the UK needs to prepare itself for the future, not least due to the need to

make the UK more competitive to drive exports and trade post Brexit. There is a strong

focus on people within the strategy and the need to address perceived weaknesses in the

skills system to ensure that people are equipped with the skills needed to gain and retain

productive jobs which also help drive economic growth. As part of this it promotes

apprenticeships, investment in technical education and a major focus on STEM skills to

address the shortages of technical skills in AME and related sectors.

The Technology Industry Futures Report9 in spring 2017 was an update of the original

papers from 2010 and 2012 and was released on the same day as the Industrial Strategy

Green Paper. It received over 1,000 responses, held 7 round table consultations and

reviewed over 50 technologies and 100 articles. Its main conclusion was that the largest

change since 2012 was the convergence and interaction between different technologies into

new products and services which defy traditional sectoral boundaries. Amongst its

recommendations was a need for government to work with industry to act as a ‘skills planner

- prepare for growing demand for worker with multi-disciplinary technical skills, and mitigate

the impact of robots and machine learning replacing unskilled and graduate-level roles’.

The Made Smarter Review10 (developed as part of the Industrial Digitalisation Review) was

published in autumn 2017 and considered how digital technologies in all their forms (e.g.

robotics and automation, AI, VR etc.) will impact UK industry. It estimated that embracing

the transformative power of digitalisation has the potential to increase UK GVA by £455bn

(cumulative) over the next decade by improving productivity, reducing waste and developing

new markets. The review included a cross cutting theme of skills, which was a recurrent

theme in all the consultations held to produce the review. The parallel development (not yet

approved or published) of the Robotics and Autonomous Systems (RAS) sector deal

proposal has estimated that RAS could led to a long term increase in employment of 7% and

be worth an additional 15% of GVA or £218billion per annum.

The Impact of AI in UK Constituencies11 (2017) looked at where in the UK would be most

affected by automation, with the South West Norfolk and Suffolk Coastal constituencies

predicted to be the most affected in New Anglia as they have more staff in low skill jobs

which are likely to be automated. The study found that between 22-39% of the workforce of

every constituency would be affected by automation argued that: ‘UK government should:

develop smart, targeted strategies to address future job displacement …. The importance of

targeting these interventions to those at most risk cannot be overemphasised. Such

8 HMG (November 2017), Industrial Strategy: Building a Britain Fit for the Future,

9 Government Office for Science (2017), Technology Industry Futures

10 HMG (2017), Made Smarter Review

11 Future Advocacy (2017), The Impact of AI in UK Constituencies

15 | P a g e

interventions could include supporting businesses to retrain employees and providing

financial and psychological support to people impacted.’

In Jobs Lost, Jobs Gained (2017)12, McKinsey & Company argues that globally they expect

15% (midpoint estimate) of current jobs will be lost to automation, but that the proportion

varies widely between countries and industries, with on balance more jobs likely to be

affected in countries and industries where industry is more developed and wages are higher

(such as the UK). They expect the overall economy and the demand for workers to grow

due to economic growth, but as with other reports argue that these changes ‘will challenge

current education and workforce training models, as well as business approaches to skill-

building’. They suggest that the change seen in the economy could be faster and more

profound than in previous industrial revolutions and require major skills initiatives.

Many of the same themes have been picked up by the Engineering Employers Federation

(EEF) in a series of recent reports including:

In An Up-Skill Battle13 EEF (2016) reported that ‘we will struggle to find a sufficient

number of candidates to satisfy the demands of our sector, and too many candidates

lack the skills that manufacturers need’. The report identifies that 49% of employers in

the sector already think UK productivity is lagging our competitors and recommends that

greater focus on both management skills and technical, production skills are needed to

address this. This report also argues for supporting more young people to take

apprentices and for ‘an integrated approach to skills, both vocational and academic,

which has so far eluded the UK’ and worries that with ‘devolution of skills national and

regionally, skills policy will in the future become more fragmented and less effective.

This must, at all costs, be prevented’.

In a presentation in September 2017 the EEF14 predicted the development of an

‘hourglass’ economy for skills in the industry with a growth in higher skilled jobs at

expense of those in the ‘middle’, and predicted that 54% of all jobs in the engineering

sector would need L4+ skills by 2024. They also highlighted that 76% of engineering

employers employed at least one migrant, with the current workforce comprising 87% UK

nationals, 11% from other EU states and 2% from outside the EU. It also noted that

employers had already seen a reduction in job applications from EU nationals and an

increase in EU nationals leaving their jobs.

In Britain and the EU: Manufacturing an orderly exit15 (2016) EEF argued for a focus

on four themes to help the AME sector respond to Brexit: ensuring access to key

markets in the EU; ensuring regulatory certainty; supporting domestic investment; and,

‘addressing the UK skills gap, calling for the Government to maintain the current skills

base and a new immigration policy, which enables employers to access much needed

skills’.

12 McKinsey Global Institute (December 2017), Jobs Lost, Jobs Gained: Workforce Transitions in a Time of

Automation

13 EEF (2016), An Up-Skill Battle: EEF Skills Report 2016

14 EEF (15th September 2017), Richard Halstead, State of UK Manufacturing and Brexit, Greater Lincolnshire

Manufacturing Conference

15 EEF (2016), Britain and the EU: Manufacturing an orderly exit

16 | P a g e

In the Manufacturing Outlook 2017 Q316 the EEF reported that the sector was growing

well, with the balance of manufacturers reporting growth in Q3 running at: +34% for

output; +22% for UK orders; +33% for export orders; +25% for employment and +15%

for investment. However, the survey also found most manufacturers were markedly less

optimistic for the economy in 2018 given the uncertainty over Brexit.

In The 4th Industrial Revolution: a primer for manufacturers17 the EEF reported that

80% of manufacturers thought that the 4th Industrial Revolution would be a reality for

their business before 2025, but only11% thought that the UK manufacturing sector was

currently geared up to respond. 50% of manufacturers surveyed thought that their need

for IT and software skills would increase over the next 3 years, and the report also

concluded that ‘great leaders are needed for this to be a revolution’.

The EEF has also conducted surveys of its members in relation to the apprenticeships

levy18, with the key results from those surveyed being:

35% will pay the levy as a single employer with a wage bill of over £3m and a further

46% of companies will pay the levy as part of a group of companies;

5 in 10 manufacturers said they needed help to understand the levy system and 56%

wanted help to find the right apprentice and 6 in 10 wanted more information on the

range of apprenticeships on offer;

Manufacturers universally felt that they could not pass the cost of the levy onto their

customers and 33% expected to cut other parts of their training budget to fund the levy;

46% expected to increase their engineering apprenticeship training and 47% expected to

convert existing training into apprenticeships;

75% of employers did not expect to get back what they pay into the apprenticeship levy,

34% see no benefits in the new levy system and 6 in 10 are concerned about how to

absorb the cost pressures created by the levy.

Whilst this shows that the levy may lead to changes in behaviour, welcomed by some local

employers to address the problem of free riders in the training system (those who recruit

staff trained by other employers), the national picture also shows that along with most local

employers they are still unsure of how the levy will work in the AME sector and want help to

understand its implementation.

Locally feedback from employers was consistent with this EEF analysis in that many local

companies reported they were still uncertain about how the levy system worked and many

felt that the current approved apprenticeship frameworks did not meet their needs. In the

short term this has reduced their willingness to take on apprentices, but they believe

apprenticeships are the best type of provision and hope that numbers will increase again

once the new systems bed in and new frameworks are approved. For larger employers the

ability to share their levy with smaller companies in their supply chain has not been

communicated well to employers most of whom were not aware this would be possible.

16 EEF (2017), Manufacturing Outlook 2017 Q3

17 EEF (2016), The 4th Industrial Revolution: a primer for manufacturers

18 EEF (May 2017), Ready, Steady, Apprenticeship Levy

17 | P a g e

Engineering UK19 has also identified that:

The sector employs 19% of the workforce (5.7million employees), but has significant

challenges in terms of skills gaps with engineering being in 15 out of 32 categories

identified by the Migration Advisory Committee as open for skilled migration.

The industry expects to need 186,000 new recruits each year to 2024 and is seeing

increased interest in the sector with the highest number of apprentice starts for 10 years

at 108,000 and a 5% rise in Higher Education applicants in 2015/16. It also reported that

96% of teachers would recommend engineering careers and 51% of 11-16 year olds

would consider a career in engineering.

However, they also identified that a big gender gap remains, which appears to occur

primarily at ages 16-21, because whilst 49% of candidates for GCSE physics are female,

this falls to 22% for ‘A’ level physics, 15% for undergraduate engineering and

technology, only 7% of engineering apprentices, resulting in only 13% of engineering

jobs being held by females. This gender issue is also apparent from other work by

Engineering UK which shows that whilst 85% of dads would recommend a career in

engineering this falls to only 67% of mums.

This work suggests as corroborated by local employers that there needs to be more focus on

careers advice and guidance as whilst in general support for careers in the sector is high,

this is not translated through into applications for training by young people.

Regionally the Science and Innovation Audit (SIA) for the East of England (2017)20

identified four sectors as being particular strengths of the region: life sciences; agritech; ICT;

advanced manufacturing and materials. However, the real focus of the SIA was on the

overlaps between these four themes and how, by using technology from one of them, growth

in other sectors could be accelerated (this mirrors the central conclusion of the Technology

and Innovation Futures report 2017 above). This calls for inter-disciplinary skills and for

example the chapter summary for advanced manufacturing and materials states that: ‘‘The

AM&M sector is in the process of being transformed - particularly through digitalisation

(Industry 4.0)’

The SIA executive summary also identified digital and ICT skills as being central to the

delivery of all four themes and regional growth, stating that: ‘There is an overarching

requirement to address major issues relating to skills - particularly those relating to data

science and computer science. The Audit found shortages across all four Themes - and the

scale of the problem is such that unless addressed, it will stymie business growth across the

East of England.’ Under the section on overarching technology trends, the SIA notes that

‘Intelligent manufacturing, otherwise known as Industry 4.0 involves pervasive

digitalisation…’. These statements are consistent with feedback from local AME employers

who are witnessing at first hand the changes being brought about by digitalisation and the

challenges of finding the mix of engineering and ICT skills - ICT for real World problems as

some employers described it - that are needed to address this change.

19 Engineering UK (2017), The State of Engineering: Key Facts 2017

20 BEIS (2017), East of England Science and Innovation Audit

18 | P a g e

A number of sectoral reports for end users of AME skills, e.g. agrifood, have also clearly

identified the growing need for AME skills to support their growth. Areas such as

automation, robotics and control systems are growing in importance across industry.

Campden for example have identified that new ‘Skills and knowledge are needed including

…. Uses of technology, ‘integrated data’ and artificial intelligence (e.g. web, Internet of

Things, remote sensing, social media) to monitor and manage agricultural products’21. The

EFRA select committee (2017) also reviewed the need for labour in the food chain and

reported that the government sees the need for ‘greater automation and mechanisation of

the sector’ to help meet future labour supply challenges22.

Conclusions

What unites all the national and international reports is a belief, borne out by many local

employers, that the AME sector is on the verge of major change, which in its speed and all

pervasive nature will be as significant as any of the earlier Industrial Revolutions and thus

worthy of the term the 4th Industrial Revolution, or Industry 4.0.

However, the potential is that the changes unleashed by Industry 4.0 will affect virtually

every other major sector as automation, the internet of things and robotics replace many

existing jobs.

Whilst the AME sector could be the major beneficiary of this change, consultees were keen

to point out that increasing the supply of skills in engineering and linked enabling disciplines,

such as ICT, will determine whether New Anglia can gain from this process of change.

With the demand for the engineering, automation and digital skills needed increasing across

all sectors and not just in those companies in the AME sector directly, employers were also

concerned that they will face increased competition for skills and thus not be able to benefit

from these changes which are global in nature.

Failure to act on the skills needed by Industry 4.0 would lead to loss of employment in many

other sectors which will invest in new technology, but which will buy this technology from

AME suppliers in other regions, without the area seeing the gains which could be delivered

within the AME sector locally if it is able to meet these needs.

Addressing these challenges is not easy and requires a commitment from employers and

government to work together on strategic challenges such as how to address the gender

imbalance in engineering, secure the skills needed for Industry 4.0, both through new

entrants and retraining and to ensure that engineering and manufacturing skills are available

both within the AME sector and to other employers who need them.

21 Campden, Scientific and technical needs of the food and drink supply chain 2018-2020

22 EFRA Select Committee (2017), Feeding the nation: labour constraints, Seventh Report of Session 2016-17

19 | P a g e

The AME Sector Skills Plan

The AME sector skills plan will balance partnership development to help the AME sector act

collectively, with shorter term locally responsive actions to meet immediate challenges and

longer term strategic and often arger scale development of new centres and programmes to

meet the long term workforce and skills needs of the sector.

Priorities for Action

The analysis of need from the consultations and reports on the advanced manufacturing and

engineering industry, shows that the AME sector faces a series of current and future

challenges in sourcing the workforce and skills needed to support both current operations

and to deliver growth.

However, there was also clear evidence that local employers are very aware of the

challenges facing the industry and many are willing to actively work with other employers

and stakeholders to address future skills supply issues.

The priority actions set out in the plan are designed to address a set of strategic objectives

proposed by employers:

The need to mobilise industry leadership in helping meet future workforce and skills

supply challenges and in ensuring that providers have clear guidance on the skills

needed - there was agreement that the scale and complexity of the challenge means

that training providers and government cannot meet the industry’s needs without the

active leadership, input, guidance and support of employers;

The need to rise to the challenges and opportunities afforded by Industry 4.0 as the

lines between engineering and digital technologies blur to deliver smarter, more

productive manufacturing processes;

A strategic imperative to plan for major projects or programmes in advance which

will increase the demand for AME skills e.g. the potential development of Sizewell C

would help grow the local AME sector substantially, but unless this is managed could in

the process ‘poach’ staff from other AME employers in the region;

The pressing need to build on and co-ordinate careers advice and guidance so that

more young people, at every age from primary to post graduate level, consider a career

in the AME sector, with a particular focus needed in attracting females to an industry

which is still male dominated;

A need to focus more on applied skills development so that apprentices and students

gain the real world work experience needed to be useful members of the team in AME

sector companies from day one, including by developing new applied HE provision;

The need to ensure that training programmes have access to modern facilities and

equipment to support new curriculum areas such as Industry 4.0, in most cases by

working with industry to meet this need rather than trying to create all the facilities

needed in educational centres which will rapidly be out of date;

The need to increase the supply of tutors with first-hand experience of the latest

technology and how it is applied in the workplace, so that students and trainees are

equipped with the skills needed by employers.

20 | P a g e

Need for a Step Change

Throughout the consultation process it was clear that employers and providers shared a

view that the demand for AME skills was likely to see a step change in three important ways:

Total demand - the total demand for AME skills will increase as the use of automation

and robotics, self-driving vehicles and other similar developments advance;

New Skills and Combinations of Skills - the nature of the skills needed will change

quickly as technology advances and boundaries between disciplines become blurred;

Diversify into new sectors - as the demand for AME solutions moves into new sectors

(e.g. health care) and affect the demand for skills and employees with AME skills across

many other industries.

Consultees felt that incremental, organic growth of training and skills provision was likely to

mean that the current shortage of AME skills becomes a crisis and constrains future growth

of the sector.

Addressing this required a step change in three areas:

Employers need to work together as they are all facing similar challenges and, by

pooling their demand, can make it much more viable for education and training providers

to be able to respond to their needs. This is true of both their need for new recruits as

well as the pressing need for more CPD as skill requirements change.

Providers need to work together to create clear progression routes, attract new talent to

the provision and to ensure that collectively the shortfall in skills for the growth of the

industry can be addressed.

Funders and strategic bodies including funding bodies, the LEP and Councils need to

agree an investment strategy to support the employer and provider base in delivering the

step change in employer engagement and provider response needed.

There is a need to change the national funding rules, standards and frameworks to make

them fit for purpose, so that they are much less prescriptive to enable employers and

providers to work together to ensure provision meets market needs. The current frameworks

and standards are dated, have significant gaps and are frustrating the development of

courses which meet emerging needs which will grow the AME economy e.g. Industry 4.0.

One area in which more collaboration is needed is in bringing together major investment

programmes in AME skills and knowledge provision, including:

Institutes of Technology;

The Institute of Productivity;

Major investment programmes in AME being delivered by providers including UEA, West

Suffolk Colleges, East Coast College, College of West Anglia, City College Norwich and

Easton and Otley College.

Whilst recognising that each of these developments are separate and will have to ensure

they have a viable business plan, by working together real synergies which could benefit

students (e.g. progression pathways) and employers (e.g. access to new skills) could be

unlocked, which in turn would support economic growth and the viability of all the individual

developments.

21 | P a g e

AME Sector Skills Plan Delivery

The delivery of the sector skills plan should be led and supported by industry. The New

Anglia Advanced Manufacturing and Engineering (NAAME) sector group has a key role to

play in providing this sector leadership.

To give focus to the skills aspects of AME sector development a Skills Group should be

established to advise on skills development for the sector in Norfolk and Suffolk. The Skills

Group should report to both the NAAME Board and LEP Skills Board to ensure that it both

draws on the needs of the industry and informs skills investment and planning by the LEP.

In developing the AME Skills Group an emphasis will be placed on promoting collaboration

and joint working between:

Employers to identify common issues which need to be addressed and to identify ways

in which they can pool their resources to secure the future workforce needed;

Employers (either individually or collectively) and education and training providers on

areas including the promotion of AME careers, the development of new or enhanced

programmes, securing the specialist staff and facilities to train the workforce;

AME employers/training providers and funding (ESFA, HEFCE etc.) or economic

development bodies (Councils and the LEP), to ensure that public sector resources are

aligned with industry needs given the magnitude of change which is anticipated in the

skills needs of the sector in the next decade and beyond.

The collaboration and joint working proposed between employers and the education and

training system will focus on both short term actions at sub-sector or local level, as well

longer term more strategic programmes. The role of the AME Skills Group will in most cases

be confined to supporting projects led by employers and/or training providers, but for larger

projects the Skills Group will ensure that at least one of its members takes an oversight role

in projects it sponsors to ensure that the lessons learnt are disseminated.

Whilst it is expected that the Skills Group will develop its own rolling project plan, with

ongoing input from employers and providers, five initial skills interventions are proposed to

address the agreed strategic objectives:

1. Industry 4.0 Challenge Programme working across the AME and digital tech sectors in

New Anglia to ensure that the New Anglia AME sector has the skills needed to deliver

new manufacturing and engineering technologies;

2. Careers of the Future Programme to ensure that the sector projects the career

opportunities in AME effectively, both to school age and older students;

3. Developing AME Course Provision to ensure that courses meet changing employer

needs and that this is supported by government funding frameworks;

4. Physical Facility Development Programme by identifying opportunities to share

resources between industry and training providers and to create new or enhanced

physical facilities and training centres;

5. Tutor Development Programme to increase the supply of tutors, full and part time, to

help deliver the skills development needed by the AME sector.

It was also recommended that there is a key role for the Skills Group in advocating with

employers that the sector should take a more proactive approach to promoting the industry

as a career of choice. Whilst it is recognised that some employers are very active on skills

22 | P a g e

and careers issues, consultees reported frustration that many other employers in the sector

still see the challenge as one for others e.g. Colleges or national sector bodies, to address.

A sector based group which championed careers promotion and brought employers together

in New Anglia to help the whole sector work with providers to ensure provision meets its

needs was therefore seen as potentially very beneficial to the growth of the whole industry.

Local and Regional Level Action

Whilst most of the proposed actions are focused on the New Anglia level, given the scale

and diversity of the AME sector, consultees were also clear that leadership at the sub-sector

and/or local geographic level was also needed for some of the proposed interventions.

Delivery of the region wide plan should build on successful local initiatives, seek to fill gaps

where these exist and drive forward a coordinated regional response.

Consultees also strongly supported working with other sectors which need AME skills e.g.

ports and logistics, energy, agrifood tech, given the shared challenges. This could

encompass both sharing course provision as well as promoting ‘technology’ intensify careers

and potentially longer term ambitions such as a Science Centre to promote STEM careers.

Strategic Overview of the proposed skills interventions

The relationship between these interventions is:

Co-ordination by NAAME Skills Group

Clarity on sector development potential, resource needs and industry voice to help shape

and steer skills provision and interventions which meet employers needs

Industry 4.0 Challenge Programme

Cross cutting regional drive to lead the deployment of Industry 4.0 technology & systems

to ensure the AME sector in New Anglia remains competitive and market focused

Careers of the

Developing AME

Physical Facilities

Tutor Development

Future

Course Provision

Development

Programme

Programme

Careers advice

New FE/HE courses

Buildings & centres

Tutor supply

Work experience

CPD provision

Access to state of

CSR and industry

the art equipment

release programme

Supported by: employers, ESFA, HEFCE, LEP, EU structural funds (and forthcoming

Shared Prosperity Fund)

Funding, strategic support and co-ordination of match funding and industry

23 | P a g e

Proposed Skills Interventions

Intervention 1 - Industry 4.0 Challenge Programme

Rationale: Industry 4.0 and the Internet of Things (IoT) are predicted to advance very

rapidly in the AME sector in the next 5 years and, unless the sector addresses the skills

challenges this creates, there is a real risk that it will reduce the competitiveness of the

local AME sector. Similar challenges in relation to digital skills were identified in the Life

Sciences and Bio-economy and AgriFood Tech sector skills plans and addressed in the

ICT and Digital skills plan, and the opportunity should be taken to work across these

sectors to identify common actions which can be taken.

Action to be Taken: the challenges and opportunities arising from Industry 4.0 will affect

every aspect of the AME sector and many of the end users the sector supports. It is also

a broad challenge and will require substantial investment over an extended period of time

from both industry and the public sector. Proposed actions include:

Developing the Institute of Productivity to lead work on the automation agenda for

Norfolk and Suffolk to ensure that the manufacturing sector can embrace new more

efficient production processes with a strong emphasis on CPD. It is critical to align this

with the proposed Institute of Technology and investments being made by Colleges

and Universities

Ensuring that New Anglia develops links to sector deals which are focused on these

challenges and builds Industry 4.0 into the Local Industrial Strategy;

Promote the uptake of Knowledge Transfer Partnerships (KTPs) and innovation

funding which draw on and develop new higher level skills in Industry 4.0 in New

Anglia AME sector companies;

Developing challenge led tasks on coding, data analysis and automation to use with

young people based on Advanced Manufacturing and Engineering problems which

can be used with schools, Colleges and projects such as Stepintotech.

Leadership: this action needs to link end user demand from employers represented by

NAAME with the ICT/Digital sector (via TechEast) and the Institute of Productivity to

develop a large programme led by industry and key stakeholders.

When: this action is critical to the AME sector’s future and so a programme should be

developed and launched by summer 2018 and inform the implementation plans for the

New Anglia Economic Strategy.

Resources and support: the proposed Industry 4.0 challenge programme should work

with the LEP to identify a substantial medium to long term investment package which

prepares New Anglia for the challenges and opportunities of Industry 4.0. The objectives

of this programme, CPD, knowledge led growth, innovation and competitiveness, align

well with the New Anglia Economic Strategy, the UK and Local Industrial Strategy, and the

LEP should work with employers and providers to develop proposals for major bids to

national programmes and the forthcoming Shared Prosperity Fund.

24 | P a g e

Intervention 2 - Careers of the Future Programme

Rationale: the AME sector is facing major challenges with staff supply and needs to

attract more applicants, including those from non-traditional backgrounds, by co-ordinating

the projects and initiatives working on this challenge locally, regionally and nationally.

Action to be Taken: promoting the AME sector as a career of choice requires actions by

employers, regional and national sector programmes and providers to be co-ordinated into

one comprehensive offer. The programme should target all ages and backgrounds, with a

focus on: 9-18 age group as they make career choices; female students who are under-

represented in AME; and, explaining career paths and salaries in the AME sector to

students and parents. The successful Opito scheme in the energy industry was a model

which consultees supported. The coordination of careers advice should:

Embrace and build on the work being undertaken by specialist local programmes such

as Stepintotech, which works with young people on digital and engineering challenges

and Beacon East and Cambridge Launchpad both of which support business

education partnerships and work on careers advice;

Promote case studies of early career AME sector workers who have good jobs, career

prospects and salaries to dispel misconceptions about the sector;

Align industry and learning provider investment with regional and national programmes

run for STEM and by engineering sector bodies, with employers keen to see a ‘reboot’

of the STEM ambassador scheme which they feel is effective when delivered;

Influence school curriculum delivery by promoting examples of new technology which

can be linked to curriculum content e.g. ICT and digital or physics and maths;

Support delivery by employers and Enterprise Advisors at the local level by providing

them with the support and development needed to work effectively with schools.

The provision of work experience also needs improving to help ensure that young people

are both given meaningful experience of the AME sector and then supported, through

careers advice, to understand how to move forward with an AME career. Employers are

keen to see Norfolk schools adopt the more flexible approach to work experience seen in

Suffolk to ensure that more employers can support work experience for more students. It

is also vital that barriers to work experience such as H&S or the perception in some

schools that it is challenging to offer work experience in the AME sector is addressed.

Leadership: the NAAME sector body should take ownership of this programme and

through its Skills Group champion the delivery of future careers advice to the sector.

When: the careers of the future programme should be established by 1st September 2018.

Resources and support: resource needs for co-ordination are comparatively modest but

it is important that a central resource, guaranteed for 3-5 years is secured to help co-

ordinate careers delivery. The majority of resources needed for delivery are already in

place, through regional programmes (e.g. icanbea, Enterprise Advisor Network) and

nationally (e.g. EEF, tomorrowsengineers.org.uk, access IET provision). In addition many

businesses in the sector work with schools and FE/HE to promote the industry.

25 | P a g e

Intervention 3 - Developing AME Course Provision

Rationale: progression from FE to HE courses in the AME sector needs to be improved to

meet the large predicted increase in the demand for L4-6 qualified job. The existing

workforce will also need to undertake further training as the development of Industry 4.0

changes the nature of many roles in the sector. Both challenges require new and

developed course provision which is more flexible to meet employer and students’ needs.

Action to be Taken: to facilitate improved rates of progression from age 13-14 to further

and higher education in the AME sector courses must meet both students’ and employers

needs through combining practical and theoretical knowledge, with a focus on the

application of skills. In addition to action locally the sector must engage with national

funders, via the LEP and sector bodies, to promote more flexible national standards and

frameworks which allow local providers and employers to work together to design courses

which meet market needs. The focus for new course development includes:

Development of progression pathways from existing FE full time courses to HE;

New course types including developing Higher Apprenticeships with employers to

meet the gap in applied higher level skills development in the AME sector;

Course development also needs to facilitate FE courses which allow engineering and

ICT to be combined to meet the need for Industry 4.0 provision;

New modes of delivery which are responsive to industry needs e.g. short block

release, use of blended learning or seasonal provision which allows students to work

as a part of their company team whilst learning at the same time on a flexible basis;

Filling gaps in current course provision e.g. applied engineering design to ensure that

employers have access to engineers who can design and prototype new technology;

Working with schools and FE providers to develop progression routes from STEM

subjects into the AME sector, by linking to ‘T’ Level developments as these are

developed over the next few years.

Training providers and industry also need to work collaboratively to develop specific

courses or modules/units to equip the existing workforce for new challenges, such as

Industry 4.0, through CPD courses which help employers develop new skills.

Leadership: the industry, led by NAAME, will work with Colleges and Universities to

develop new models of course provision which are responsive and flexible to industry

needs and which attract non-traditional entrants.

When: the development of new courses is an ongoing process, but given the rapid

increase anticipated in technology linked to Industry 4.0, it is vital that new provision in this

area is developed in time for delivery in 2018 or 2019.

Resources and support: the resources required are mainly a commitment by Colleges

and Universities in conjunction with industry partners to develop new courses and

technical training programmes. As well as influencing the design of the new Shared

Prosperity Fund (with the LEP), the AME sector must work with national funding bodies to

argue for a more flexible set of standards and frameworks which meet industry needs.

26 | P a g e

Intervention 4 - Physical Facility Development Programme

Rationale: the AME sector is seeing rapid changes in the technology used and ensuring

access to modern state of the art training facilities and equipment is essential to meet

future skills needs. Training providers can struggle to afford the large investment and re-

investment needed and therefore training providers and industry should work together.

Action to be Taken: providers, employers and the LEP should work together to identify

and fill gaps in physical training facilities in the region under the framework a strategic

investment plan which aligns physical facility and staff development. A clear business

plan will be required for each development which reviews existing provision (inside and

outside the LEP area) and the business case. The following initiatives were identified as

being desirable as part of an overall strategic investment plan for AME sector skills:

The Institute of Technology and Institute of Productivity would both help position New